An output of 30 to 40 ducts/hour

A minimum of 30% automation

A pack tailored to craftsmen and professionals

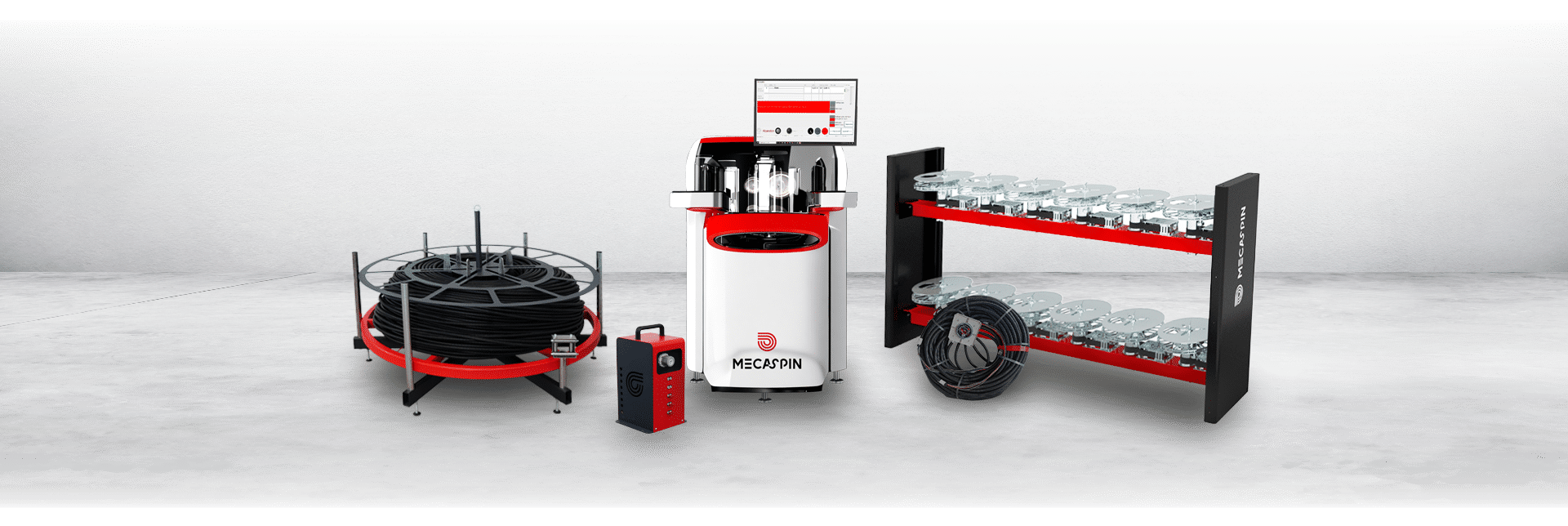

INCLUDED IN THE STARTER PACK

Everything you need to automate your production

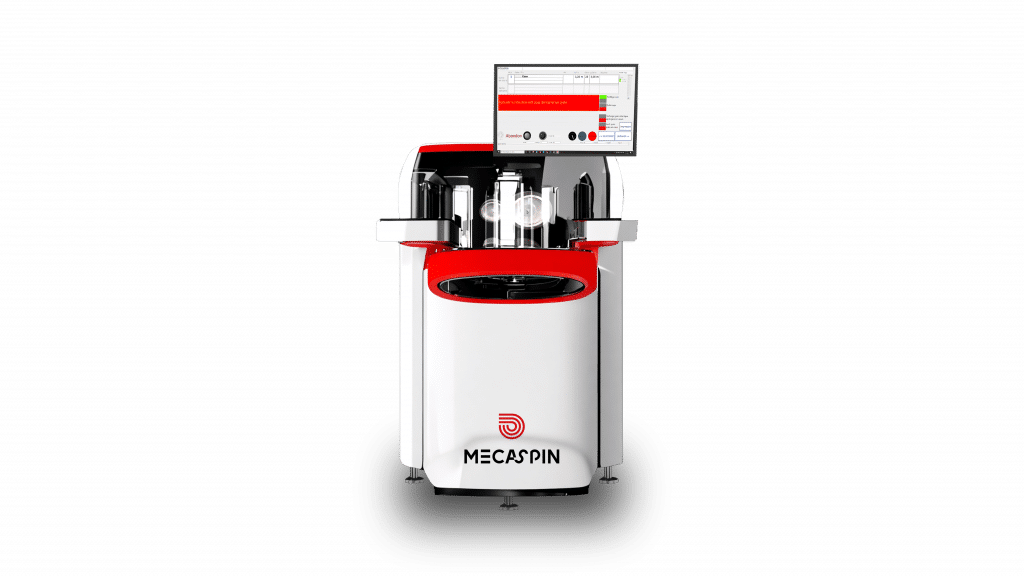

Semi-automatic sheath pre-wiring MS01

- AUTOMATION 60%

- CADENCE 80%

- Modularity 50%

Wire management equipment

Unwinding gantry

Floor-mounted reeling gantry to support the various tubes for the passage of electrical wires. The gantry is a mechanically welded steel assembly, assembled and erected by Mecaspin teams.

Duct management equipment

Hose reels

Fitted with a connected braking system, the MECASPIN ICTA sheath dispenser ensures optimum unwinding of the sheath in the pre-wiring machine. Combined with Mecaspin prefeeders, the liner unwinder facilitates unwinding operations and prevents accidental unwinding of the liner.

Inclued | |||

Automatic duct cutter | |||

Label editing | |||

Measuring lengths | |||

Wire propulsion | |||

Controlled braking of reels | |||

Anti-clogging detection | |||

Electric box unwinding system | |||

Duct track | |||

Automatic wire cutter | |||

Reading production files | |||

Storage of ducts on trolleys | |||

Automatic nozzle change | |||

Sheath tying system | |||

Automatic wire selection | |||

Automatic duct selection | |||

Automatic label application | |||

Box assembly equipment | |||

Storage of finished products | |||

Packaging of finished products |

Let's configure your pack together

Do you have specific needs?

We can help you configure your installation to meet your production objectives.

CUSTOMER CASE STUDY

Take a look behind the scenes of a Mecaspin turnkey installation

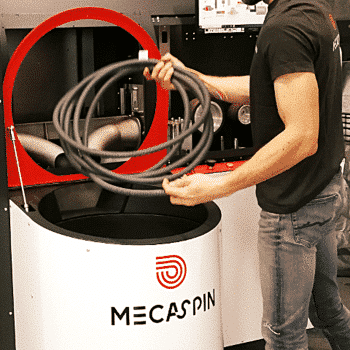

Presentation of a STARTER installation

Mecaspin recently implemented an ergonomic, high-performance wiring solution for one of our customers, a craftsman specializing in electrical installations. He and his team benefited from the Starter pack, containing the MS01 semi-automatic pre-spinning machine, the sheath reel and the wire reel gantry, which perfectly met their specific needs. The installation process proposed by Mecaspin was efficient and fast, adjusting the installation to the constraints of the space. This illustrates our ability to provide tailor-made solutions that optimise the working environment. To offer the best possible working conditions, Mecaspin has focused on the implementation of customised solutions, adapted to each workshop and company. Mecaspin continues to offer tailor-made solutions for a variety of structures. Our expertise and commitment to excellence make us a trusted partner for any turnkey installation.

They trust us

"Our operators appreciate the machine's speed and ease of use".

Romain

"The computer files for the cabling arrive at the machine very simply".

Eric