Semi-automatic sheath pre-wiring MS01

prespinning machine MS02

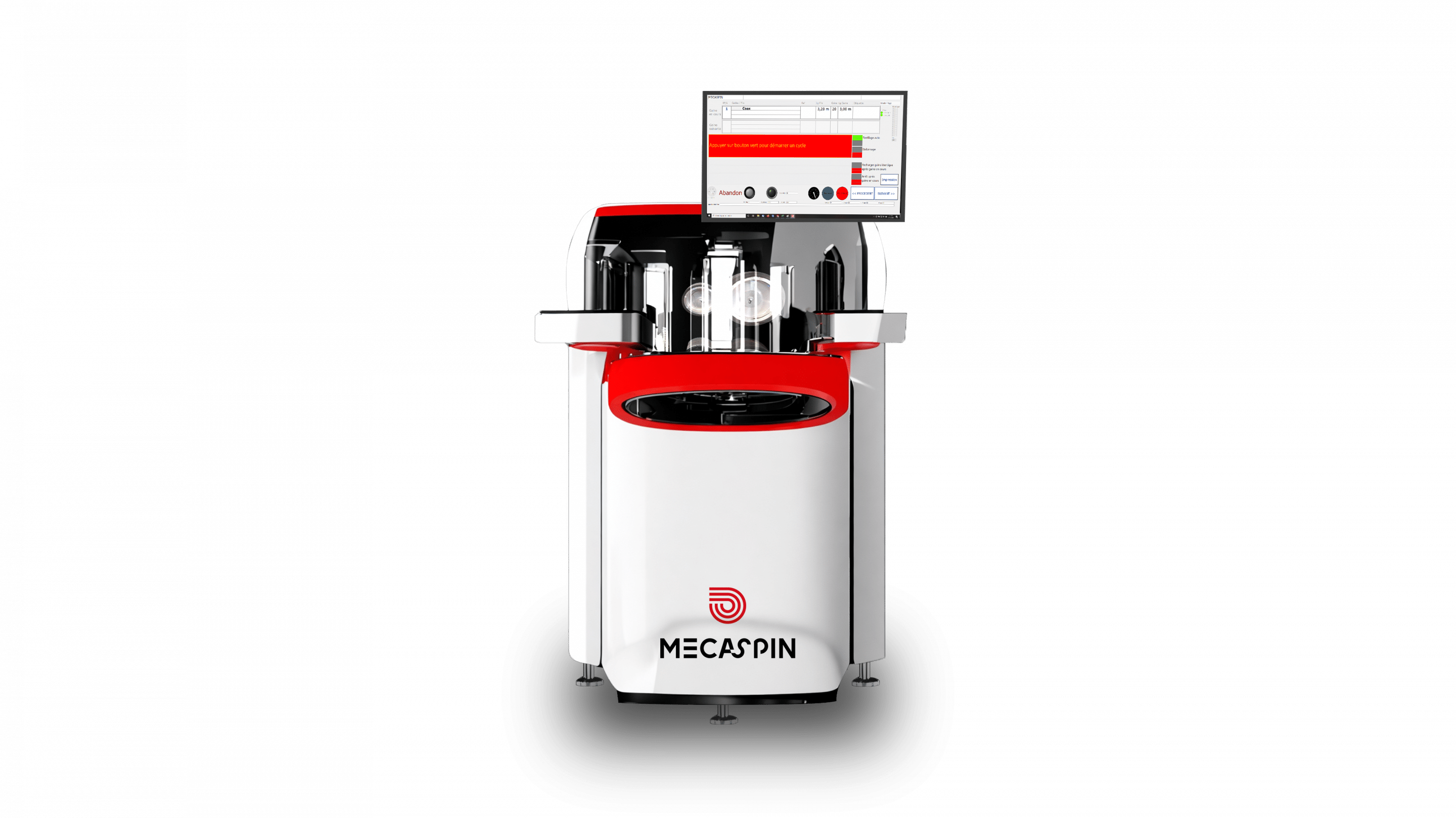

MS03 automatic pre-spinning

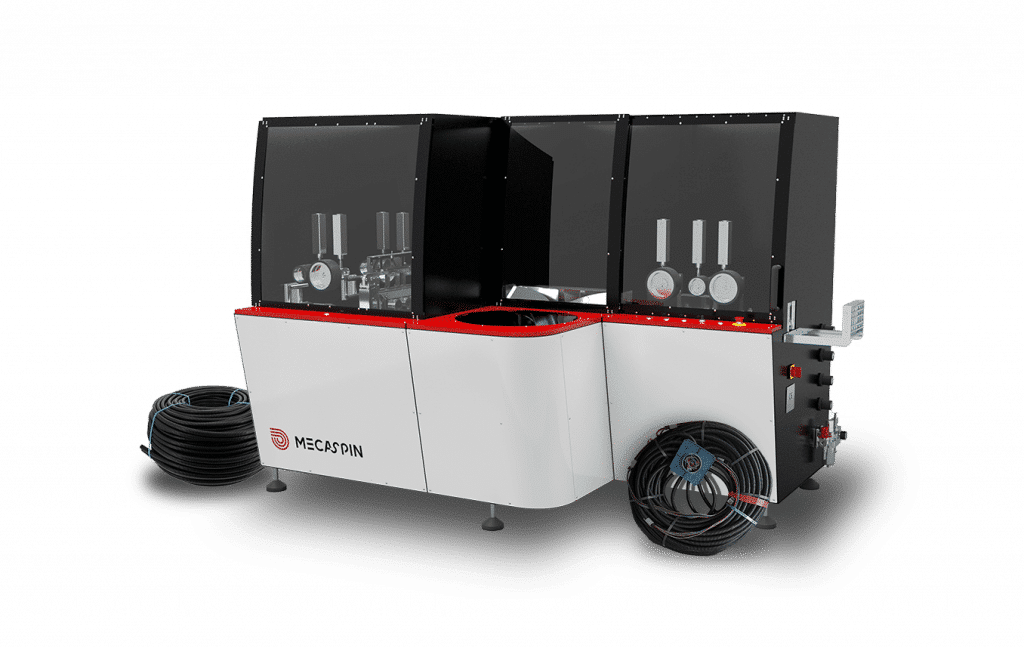

Modular industrial pre-wiring MS04

Wire sorter

Complementary modules

Mecaspin, your partner for the manufacture of home automation, hydraulic and electrical octopuses wiring

OUR wire and sheath power packs

Mecaspin's wire and sheath dispensing packs optimise the organisation of your workshop, reducing handling times and increasing productivity.

Pack

Unwinding of conduits

The Mecaspin sheath feeder pack ensures continuous, effortless feeding, improving the fluidity of your operations and increasing your productivity.

Pack

Unwinding of Wire

Mecaspin's wire feeder pack ensures even, hassle-free distribution, optimising your output and making your day-to-day tasks easier.

We invite you to our showroom

Come visit our showroom and test our pre-assembled wiring under real conditions, as well as our various peripheral equipment, accompanied by one of our technicians.

FAQ

Qu'est-ce qu'une pré-fileuse de gaine électrique?

A sheath pre-wiring is a machine used to thread sheaths (or tubes) onto electrical or optical wires or cables. It makes the spinning process much easier by automating certain key stages, such as :

- Power supply: The machine can receive wires or cables continuously, without having to cut or stop them each time.

- Positioning: The pre-spinning aligns the wires or cables in the sheath precisely and uniformly, avoiding manual placement errors.

- Clamping: Thanks to its automatic clamping devices, the pre-wiring holds the wires or cables firmly in place throughout the process, guaranteeing optimum work quality.

Sheath pre-spinning are generally used in the manufacture of electrical and optical cables, the automotive industry, aeronautics, telecommunications and renewable energies.

Quels sont les avantages des préfileuses ?

Sheath pre-spinning offer a number of significant advantages. Firstly, they increase productivity by mechanising the spinning process, enabling more wires and cables to be processed in less time. Secondly, these machines contribute to a substantial reduction in costs by minimising errors and, consequently, reducing labour and material costs. What’s more, the pre-spinning guarantee exceptional quality thanks to their precision and repeatability, which ensures uniform quality when threading the sleeves. This improves the reliability of finished products. Finally, one of the undeniable advantages of these machines is their improved safety. By eliminating the need for operators to manually handle wires and cables, they considerably reduce the risk of accidents or injuries in the workplace.

Comment fonctionne une machine de préfilage?

The process begins by loading the wire or cable. Depending on the model, this loading can be carried out manually or automatically. The yarn is then carefully guided by pulleys or rollers to the pre-spinning station, the heart of the operation. Once at the pre-wire station, the wire or cable is passed through a specially designed pre-wire head. This head contains a tapered hole precisely adjusted for the size of wire or cable and sheath to be installed. At the same time, the liner is prepared on a device, often a carousel. It is fed to the pre-wire head at the same time as the wire or cable. Under a certain tension, the wire or cable is inserted into the sheath. This procedure requires great precision to avoid damaging the conductor and to ensure flawless installation of the sheath. Once the sheath has been correctly installed, the wire or cable is redirected to the machine outlet.

Comment choisir la préfileuse de gaine adaptée à vos besoins ?

There are a number of crucial criteria to consider when choosing a sheath pre-spinning. Firstly, the machine must be compatible with the type of wire or cable you are using, whether electrical, optical or other. This guarantees efficient working and prevents potential damage to your cables. Secondly, the size of the sheaths to be processed must comply with the machine’s specifications, a necessary condition for maintaining efficient production. What’s more, the volume of production you need to manage will influence your choice of pre-filter, which can vary in speed and capacity. Estimate your volume requirements precisely to make the best choice. Finally, the degree of automation you wish to incorporate into your production may also dictate your choice of pre-wiring models equipped with automatic feeding, numerical control or programming systems.