INCLUDED IN THE PREMIUM PACK

Design your workshop for even greater performance

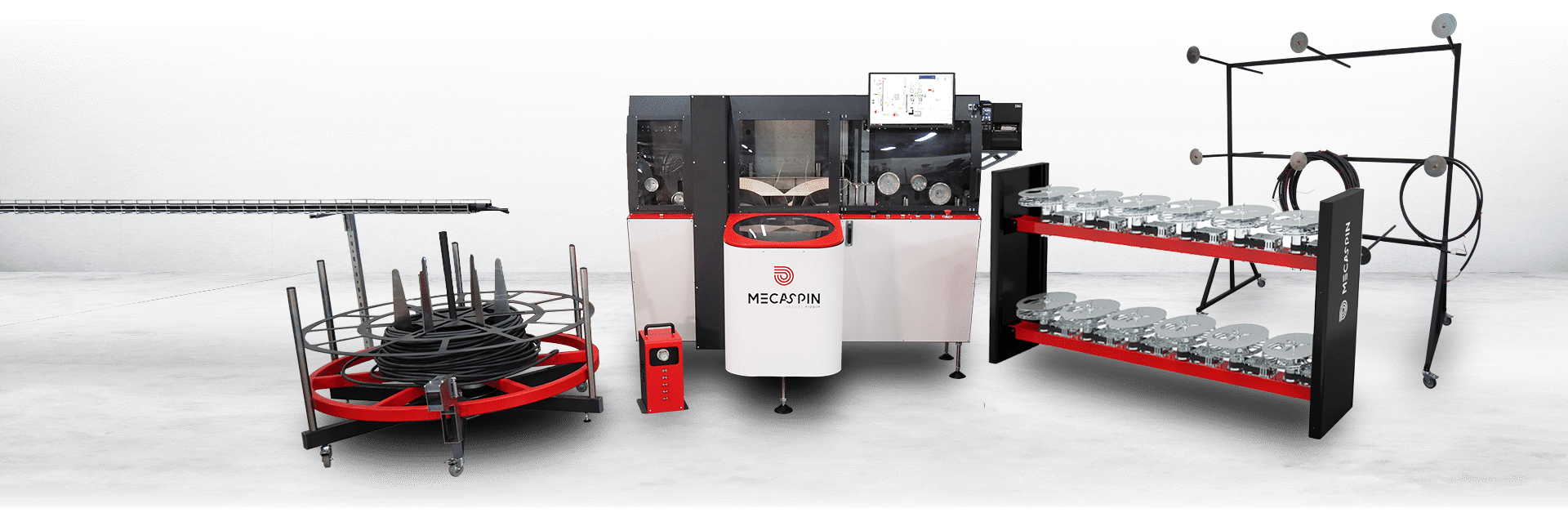

MS03 Sheath Pre-spinning

- AUTOMATION 80%

- CADENCE 80%

- Modularity 60%

A pack designed for octopus wiring and specialists

Wire management equipment

Unwinding gantry

Discover our gantry reel equipment, designed to simplify your workshop and save you time. Thanks to this equipment, you can organise your workshop as you see fit and optimise your working time. Don’t waste any more time looking for your lost wires: our installation will keep them neatly tidied up and ready for use.

Wire management display

The wire feeder, an essential piece of equipment for your spinning system, allows you to organise and separate the different wires by placing them at the right height for easy handling. This equipment guarantees easy unwinding of electrical wires and reduces the risk of tangles. Optimise your entire production with this Mecaspin exclusive. Read more

Rolling racks

Trolleys are the perfect way to store your filled crowns and improve the organisation of your workshop. Its large number of branches means that ducts can be stored for several jobs. Last but not least, its castors make it easy to move ducts and allow simplify moving your production Read more

Duct management equipment

Hose reels

The MECASPIN ICTA sheath dispenser, with its connected braking system, makes it easy to unwind your sheaths. This device makes your production process smoother and simpler by preventing your sheaths from unwinding. Read more

Duct sleeves

Mecaspin sheaths are used to guide and orientate the sheaths from the reels to the MS03 pre-wiring machine. Thanks to Mecaspin’s expertise, the sleeves can be adapted to your installation and easily installed in your workshop. Perfect for easily organising and optimising your octopus wiring workshop. Read more

Inclued | |||

Automatic duct cutter | |||

Label editing | |||

Measuring lengths | |||

Wire propulsion | |||

Controlled braking of reels | |||

Anti-clogging detection | |||

Electric box unwinding system | |||

Duct track | |||

Automatic wire cutter | |||

Reading production files | |||

Storage of ducts on trolleys | |||

Automatic nozzle change | |||

Sheath tying system | |||

Automatic wire selection | |||

Automatic duct selection | |||

Automatic label application | |||

Box assembly equipment | |||

Storage of finished products | |||

Packaging of finished products |

Let's configure your pack together

Do you have specific needs?

We can help you configure your installation to meet your production objectives.

CUSTOMER CASE STUDY

Take a look behind the scenes of a Mecaspin turnkey installation

Presentation of a PREMIUM installation

Mecaspin recently designed a complete, ergonomic and high-performance spinning solution for “La Compagnie des Pieuvres”. Mr Langlois and his team benefited from a turnkey installation, tailored to their specific requirements.

The installation supplied by Mecaspin proved fast and efficient. To achieve this, we used our know-how to adapt the installation to the company’s space constraints. It ‘s a demonstration of our ability to design tailor-made solutions for every customer, guaranteeing an optimized working environment.

With the aim of providing the best possible working conditions, Mecaspin focuses on providing tailor-made solutions. We adapt to the size and configuration of each workshop and company , responding to every specific need.

Mecaspin continues to offer customized solutions for a wide range of companies. With proven expertise and a commitment to excellence, we stand out as a reliable partner for all your turnkey installation needs.

They trust us

"Our operators appreciate the machine's speed and ease of use".

Romain

"The computer files for the cabling arrive at the machine very simply".

Eric