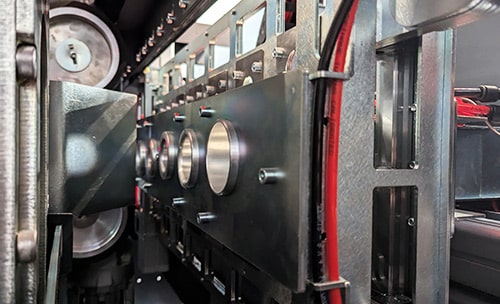

Sheath pre-wiring MS04

- AUTOMATION 100%

- CADENCE 100%

- Modularity 100%

Features

Sheaths and wires are sorted by computer according to diameter, colour and length. Sheath and wire changeover times are optimised.

Up to 30 metres in a straight line on wires in 16, 20, 25, 32 and 40 mm C.E.I. ducts.

Plumber’s sheath, wire and PER automatically cut to length.

Labels printed automatically at the end of the duct with manual application.

Wrapping when unloading extruded sheaths.

Operator interface via intuitive control screen with multiple levels of access for maintenance, programming and operation

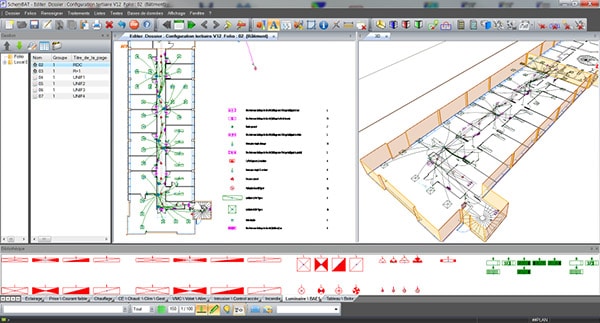

Native integration of drawing books from FTZ Schembat, Desa, DWG and Sifial for launch in stand-alone production on the MS04 machine

Native integration from Schembat, Desa, M-elecDWG, Excel in plug and play

The MS04 pre-wiring has been designed to manage interfaces with the software and tools used by customers.

FTZ SCHEMBAT, DESA or M-ElecDWG can be interfaced with your machine to directly integrate wiring and electrical octopus wiring .

The MS04 can also be set up using Excel or manually to handle any situation.

Guaranteed productivity gains, simple installation

Save time with a spinning speed of 3 metres per second!

Save money by avoiding unnecessary raw material waste thanks to the machine’s high cutting precision. Accuracy of 1 cm per 10 m.

The machine vibrates very little, so there’s no need to secure it to the floor.

The machine is easy to operate thanks to its large touch screen.

Key features

- 220VAC single-phase power supply + 7 bar compressed air.

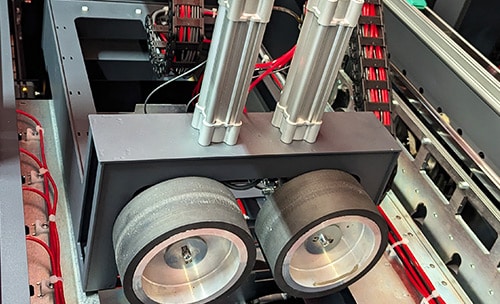

- Spinning and coiling motorisation by 750 W geared motors with bevel gears and variable speed drive for each motor, allowing differential speeds for spinning to achieve continuous tension and better spinning.

- D155 * 85 shore polyurethane roller transmission.

- Motorised corrugator (bowl diameter 550 mm) controlled and synchronised by a 750 W geared motor with bevel gear and variable speed drive.

- Accuracy of plus or minus 80 mm for a spinning or coiling length of less than 40 m.

- Proprietary software and dedicated electronic board.

- User interface with 19″ touch screen and validation button.

- Movements ensured by ISO pneumatic cylinders and island distribution system.

- Positioning by precision linear guide with recirculating ball bearing.

- Wire cutter for 70 mm² cross-section in aluminium or copper.

- Spinning and coiling motor speed 325 rpm, giving a maximum tangential linear speed of 2.5 m/s for spinning and coiling.

- Capacity for 16, 20, 25, 32 and 40 diameter sheaths, Capacity for 24 different types of wire

- Maximum cable length 40 m

Detailed description of functions

- Wires are held in place by vertical compression rollers.

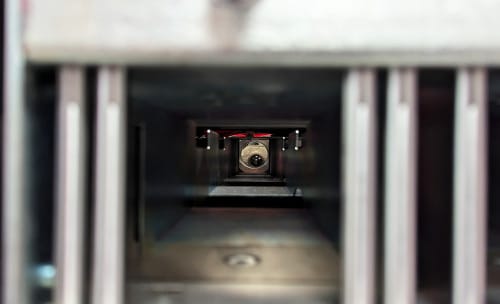

- Sheath guidance concentric with the closing plane of the rollers thanks to 5 retractable wire entry nozzles.

- Automatic rethreading of threads when there is no change in thread type, diameter, number or colour.

- Automatic threading of yarns even when the type, diameter, number and colour of yarns change, thanks to the Sorter + Shuttle module.

- The same system is used to drive and hold the wire.

- Spinning motor speed 390 rpm, i.e. a maximum tangential linear spinning speed of 3 m/s.

- Maximum traction torque 23 Nm.

- Manual pressure adjustment.

- Configurable excess wire lengths.

- Double measurement of wire length using idler and incremental encoder lOO p/t. (optional)

- Magazine with 24 threads for quick access without bypassing the coiling bowl.

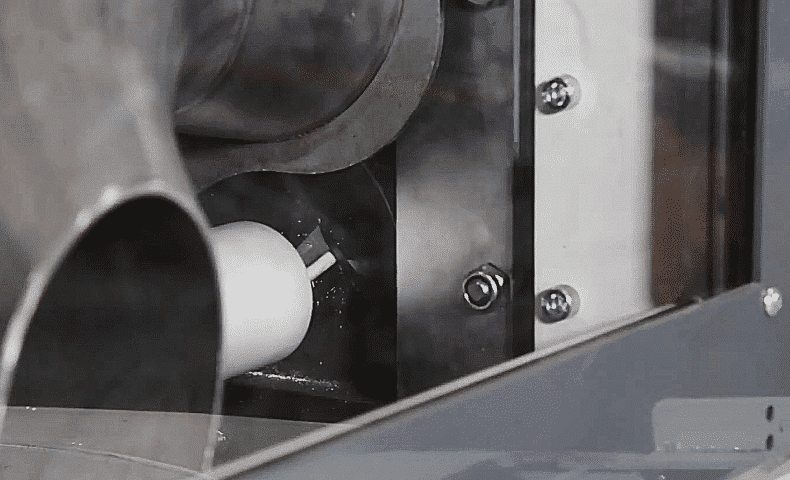

- Cutting with concentric V-guided knives.

- Less than 15 minutes for a qualified operator to change knives

- Duration of cutting action less than 3 seconds.

- Knives dedicated solely to cutting wires.

- Maximum total cross-section: 70 mm² aluminium and copper.

- Cutting by knives with a concentric U-shaped guide without cutting the wire.

- Time taken by a qualified operator to change a pair of knives less than 5 min.

- Duration of cutting action less than 3 seconds.

- A pair of knives is dedicated to each sheath diameter.

- 5 permissible duct diameters: 16, 20, 25, 32 and 40.

- Cutting of 12, 16, 20 and 25 diameter PER-coated pipes.

- Coiling motor speed 390 rpm, giving a maximum tangential linear coiling speed of 3 m/s.

- Vertical compression rollers hold the sheath in place during spinning.

- Sheath guidance concentric with the closing plane of the rollers thanks to 5 retractable wire entry nozzles.

- Unloading in 550 mm outer rings not exceeding 40 m in length.

- Uncoated wire coils.

- Maximum traction torque 23 Nm.

- Adjustable and automatic pressure setting via proportional valve.

- PER mode: for cutting PER-coated pipes to length.

- Accuracy of plus or minus 100 mm for a spinning or coiling length of less than 40 m.

- The machine has encoders

- Incremental encoder resolution: l00 p/t

- The spinner has a calibration procedure programme.

- Excel-type history of data storage: name of operator, date and time, name of file, name of sheath, sections and colour of wires and sheaths and different lengths spun and coiled.

- The ergonomics of the machine make it easier for the operator to work.

- Footprint: W2500 * D1500* H1800.

- Manufacture under the “special machine” directive

- Change in speed variation by the operator during the cycle.

- Modification of the clamping pressure to hold the PER wire and sheath by the operator.

- Adjustable settings via touch interface.

Complementary modules

OUR wire and sheath power packs

Mecaspin's wire and sheath dispensing packs optimise the organisation of your workshop, reducing handling times and increasing productivity.

Pack

Unwinding of conduits

The Mecaspin sheath feeder pack ensures continuous, effortless feeding, improving the fluidity of your operations and increasing your productivity.

Pack

Unwinding of Wire

Mecaspin's wire feeder pack ensures even, hassle-free distribution, optimising your output and making your day-to-day tasks easier.