Table of Contents

What is a sheath pre-wiring machine?

Principle and definition

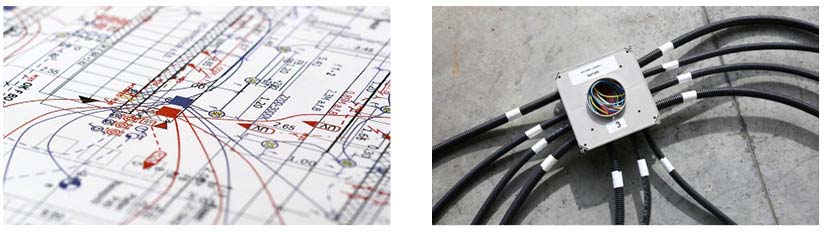

A sheath pre-threading machine is an automated machine for threading electrical wires. Designed for cabling professionals and octopus manufacturers, a sheath pre-wiring makes it possible to prepare pre-wiring sheaths without having to pull wires manually. The electric octopus wiring system has been booming for the last fifteen years. Used by professionals or private individuals for the construction or renovation of a home, the electricaloctopus wiring distributes the power supply to each socket, light and switch in a dwelling. Economical and practical, the electrical octopus wiring makes the electrical installation of a home considerably easier, as it is pre-wired, i.e. ready to install. Electric octopuses are designed and manufactured by octopus wiring makers. The design office draws up the octopus wiring plans according to the configuration of the home, in compliance with current electrical standards. Then, during the manufacturing phase in the workshop, the octopus operator threads and assembles cables and wires of various lengths in PER-type sheaths.

To avoid the tedious task of inserting wires and cables into ICTA sheaths, electrical wiring professionals are increasingly using automated industrial machines.

Advanced functionalities

Pre-wiring machines allow wires and cables to be passed automatically through an electrical sheath, making the production of electrical octopuses considerably easier. In addition to threading electrical wires into sheaths, automatic threading machines can :

- automatic cutting to length of ducts

- integration of the wires in the sheaths

- automatic cutting

- crowning of wired ducts

- labelling

Today, more and more professionals, from electricians to construction companies, are equipping themselves with a sheath pre-wiring machine to carry out electrical installations in residential and commercial buildings. Depending on the model, automatic spinning machines can vary in terms of wire type, sheath type, output and spinning speed.

What are the advantages of a sheath pre-wiring machine?

Acquiring a sheath pre-wiring machine offers significant advantages for electrical installation professionals. Save time, increase productivity, reduce costs… These are the main advantages of an automatic prefeeder:

Productivity gains

Building and installing an electrical system is one of the most time-consuming activities on a construction site. The manual insertion of electrical wires and cables into a corrugated sheath is a process that requires time and special care to ensure effective assembly without damage. Sheath pre-spinning machines automate all spinning operations – cutting yarns to length, sorting, labelling – guaranteeing considerable time savings and increased productivity. By including a large part of the process in the design office and workshop, prefabrication also reduces the time spent on site. The main technical questions can be raised from within the company.

Lower costs

Thanks tooptimized wiring and parameter control, scrap rates are considerably reduced. The machines’ cutting precision avoids unnecessary scrap on the raw material and the loss of precious copper wires.

Reduced risk of errors

Automating tasks considerably reduces the risk of errors compared to hand spinning. Sheaths, wires and electrical cables are automatically cut to length, and labels are printed as they exit the sheath. A well-designed electrical octopus wiring, correctly wired and assembled with a machine, is also the guarantee of a successful project, delivered on time.

Improving working conditions

The sheath pre-threaderindustrializes a time-consuming, physical process. All the tedious tasks – cutting, spinning, assembly – are taken care of by the machine. In addition to saving time and increasing productivity, a sheath pre-wiring machine helps prevent musculoskeletal disordersthe leading cause of occupational illness in France.

Mecaspin pre-spinning machines

Mecaspin pre-threaders are automatic, self-contained, modular sheath-threading machines for cable professionals.

Entirely designed and manufactured in France, the spinning machines MECASPIN range of spinning machines enables sheaths and wires to be sorted by diameter, color and length. The main functions include :

- Threading electrical wires into sheaths or conduits (diameter 16 mm, 20 mm, 25 mm, 32 mm or 40 mm)

- Cut to length

- The cup

- Wrapping wired ducts

- Bending sheathed PER-type pipes

Automatic threading machines can be interfaced with information from the design office, and directly integrate wiring and electrical octopus plans. Mecaspin pre-wiring are designed to handle interfaces with CAD/CAM software such as SchemBAT, Desa or M-ElecDWG, but can also be parameterised with Excel or manually. If you’re a professional in the cabling or building and civil engineering sectors, an octopus wiring operator or an electrician, you’d like to optimise your production time. Mecaspin automatic threading machines offer a high level of performance, combining efficiency and energy savings. So don’t wait any longer and come and discover our sheath pre-wiring machines!