Table of Contents

Definition

An ooctopus wiring operator is an electrical company specialising in the design and manufacture of electric octopuses wiring. The electrical octopus wirng is a kit designed to facilitate electrical installation. To find out more, read our article on the subject.

They work on new construction and renovation projects in the housing, collective or individual housing and tertiary sectors. Their customers include building professionals (house builders, property developers, installers), self-employed entrepreneurs and private individuals. Their service includes the study of the electrical installation, supply of the material (electrical wires, sheaths, electrical panel, GTL, etc.) and prefabrication in the workshop. Some companies offer to install or check the installation, depending on the type of service chosen.

The design office

In the octopus wiring company, the design office will determine the electrical requirements of the construction. They use the NF C 15-100 and RT 2012 standards as a basis for expressing requirements, which depend mainly on the number of rooms in the house and the surface area of the dwelling. They also examine with the customer the details of their project and their personal needs (additional electrical sockets, switches, heaters, light points, RJ45 sockets, etc.) to refine the request.

During the study, they define the diameter of the electrical wires for the low-voltage and high-voltage networks. They specify the diameters of the sheaths required according to the number of electrical wires to be run inside and their position in the home. They determine the number of octopuses wiring needed for the electrical installation.

Based on the house plans, the design office will draw up the electrical octopus wiring plans using dedicated wiring software such as SchemBat, Desa or M-ElecDWG.

They will then quote for the electric octopus wiring kit. If the customer carries out the installation himself, savings of up to 50% can be achieved compared with a conventional installation carried out by an electrician.

Materials and prefabrication

Calling in an octopus wiring operator can save you money on electrical equipment. This type of company has large purchasing volumes, which enables them to offer competitive prices on electrical equipment (electrical panels, electrical wiring, ICTA sheathing, etc.).

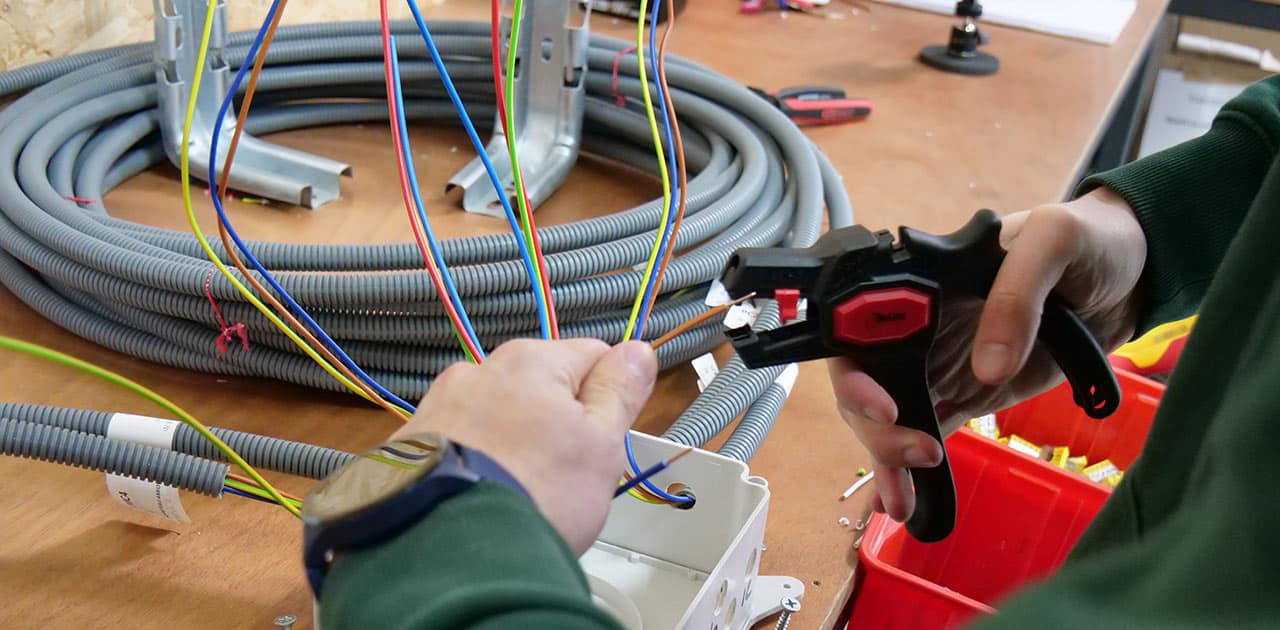

An electric octopus designer works with machines dedicated to optimizing production time, such as an automatic pre-threader which saves a great deal of time when passing wires through electrical sheaths. During the manufacturing phase in the workshop, the octopus wiring operator will prepare the kit with all the centre pots (electrical octopus heads), junction boxes, labelled pre-wired sheaths, etc. The whole unit will be assembled and connected, and the electrical panel will be wired and tested before being sent to the customer, along with a plan for installation. It takes about two weeks for an octopus specialist to complete the electric octopus wiring kit.